Seamless Integration: Enhancing Manufacturing Efficiency with CAMWorks and SolidWorks Integration

CAMWorks and SolidWorks Integration

By integrating CAMWorks with SolidWorks, and understanding this relationship, the design and manufacturing process can be greatly enhanced. CAMWorks is a feature-based CAM (Computer-Aided Manufacturing) software that automates the programming of CNC machines, while SolidWorks is a widely-used 3D CAD (Computer-Aided Design) software. The integration of these two powerful tools offers several benefits:

Seamless Workflow:

By integrating CAMWorks with SolidWorks, a seamless workflow is created between design and manufacturing. The changes made to the SolidWorks design are automatically reflected in the CAM programming in CAMWorks. Consequently, redundant data entry is eliminated, resulting in fewer errors and a shorter processing time.

Parametric Associativity:

The parametric modelling capabilities of SolidWorks are seamlessly integrated with the CAMWorks software. Any changes made to the design model, such as dimensions, features, or geometries, are automatically updated in CAMWorks without requiring manual adjustments.

Feature Recognition:

The intelligent feature recognition capabilities of CAMWorks are well known. A SolidWorks model can be analysed to find holes, pockets, and slots, and toolpaths can be automatically generated based on predefined machining strategies. It significantly speeds up the programming process.

Knowledge-Based Machining:

CAMWorks incorporates knowledge-based machining. The software captures and stores machining best practices, strategies, and parameters used by experienced machinists. Manufacturing efficiency and consistency can be enhanced by reusing this knowledge on similar parts.

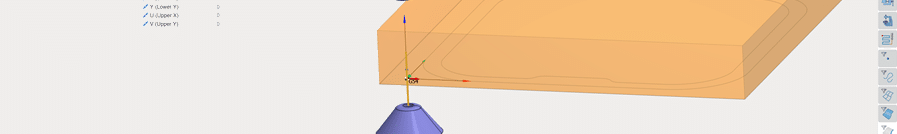

Interactive Machining Simulation:

SolidWorks CAM, powered by CAMWorks, offers users a tool for interactive simulation, allowing them to visualize machining processes before executing them on the CNC machine. By identifying collisions, errors, and inefficiencies, toolpaths can be optimized and manufacturing risks can be reduced.

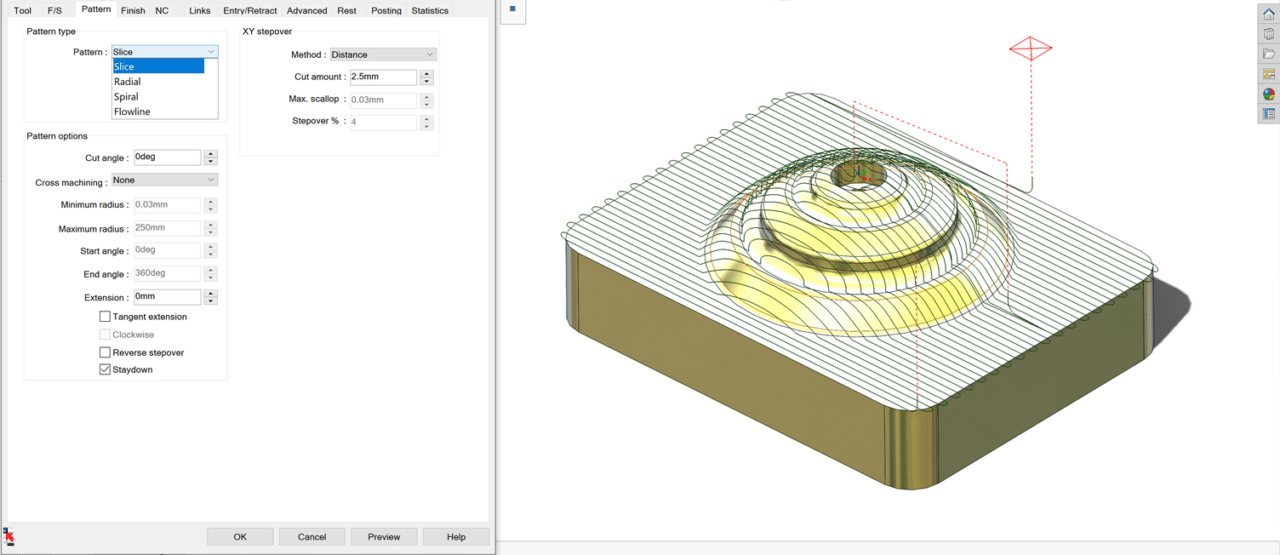

Toolpath Optimization:

The integration provides tools for optimizing toolpaths to improve tool life, surface finishes, and cycle times. Parameters, speeds, and feeds can be fine-tuned to achieve the desired results.

Post-Processing:

CAMWorks generates G-code directly from SolidWorks models. It eliminates the need for third-party post-processors and reduces the likelihood of errors during toolpath translation.

Multi-Axis Machining:

The integration allows for efficient programming and simulation of complex parts that require multi-axis machining. CAMWorks, a software platform supports 2.5-axis and 5-axis machining strategies.

Training and Support:

As CAMWorks and SolidWorks are tightly integrated products, users can benefit from integrated training and support. Consequently, learning curves are smoother and problems are resolved more quickly.

Cost and Time Savings:

Integration of CAMWorks and SolidWorks ultimately saves significant time and money. Streamlining the design-to-manufacturing process, reducing errors, and automating the process can help manufacturers bring products to market more quickly and more effectively.

CAMWorks and SolidWorks Integration: By integrating CAMWorks with SolidWorks, a comprehensive solution is offered that bridges the design-to-manufacturing gap. In modern manufacturing, this integration optimizes efficiency, accuracy, and collaboration throughout the product development lifecycle

For more information on Advantages of Solidworks CAM/CAMWorks that can add value to your business please visit https://nctools.com.au/ or call us on +61 3 8618 6884

More information on CAMWorks can be found here https://camworks.com/