How important is CAM software in manufacturing?

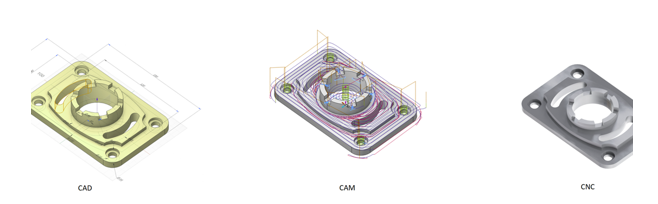

Almost every manufacturing industry utilizes CAD/CAM software today to increase productivity, improve quality of design, reduce machining time, etc. A CAD/CAM system combines Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM). CAD/CAM refers to software that is used to design and manufacture parts on a CNC machine or industrial robot. These systems can be used for simple or complex parts. There are three steps in the manufacturing process:

CAD: Design of 3D part models

CAM: Programming the 3D Model

CNC: Manufacturing the part

The advantages of CAD/CAM in manufacturing are:

They include the following:

- Integrated design and manufacturing processes reduce the gap between the two processes

- Improving machining capabilities

- Improvement of productivity of CNC machines

- Saving of materials and machining time through optimisation

and greater accessibility for clients

CAD:

A computer-aided design (CAD) system produces 2D drawings and 3D models based on geometrical parameters. CAD software can be utilized by a wide variety of engineering and design professionals. The software improves the quality of design, increases the productivity of the designer, improves communication in the design process, and improves the efficiency of the design process. CAD software is an integral part of the manufacturing process. CAD software produces a part which is then transferred to CAM for programming.

CAM:

A CNC machine tool is controlled using CAM software. The coded program instructs the CNC machine. The program is generated by using G-code to control CNC machines including lathes, mills, EDMs, etc. In terms of complex geometry, CAM software sets toolpaths that are impossible to perform manually. This software is extremely useful for manufacturing complicated products. Complicated parts become easier to manufacture when using CAM software. The use of CAM software streamlines the manufacturing process and automates a variety of operations such as drilling, milling, etc.

The software includes:

- Toolpath strategies

- Toolpath calculation module

- Simulation module

- Toolpath to G-code translation module

- G-code verification module

What is the role of SprutCAM in CAD/CAM systems:

SprutCAM is one of the most powerful CAD/CAM systems available today. A full range of automated functions are available to simplify and speed up the machining operations of CNC machines and robotics. SprutCAM offers a wide array of CNC programming solutions, including: 2, 3, 4, 5 axis milling, turning, turn-milling, 2D, 5D and 6D cutting, HSM, Swiss-type machining, multi-task machining, EDM and additive/hybrid technologies, and 6 axis industrial robot programming. The associativity between SprutCAM machining and the SolidWorks or Similar CAD Systems design model reduces errors when the model changes as well as the updating of existing models. Whenever the geometry used to define a machining operation in a SolidWorks or Similar CAD systems design is updated, SprutCAM automatically synchronizes all machining operations with the updated geometry. The system will enable all machines to be programmed within one system and enable lean manufacturing.

SprutCAM provides the following benefits:

- SprutCAM machining is fully associated with SolidWorks design models

and supports native surface/solid models - Transparent workpiece state passing from operation to operation

- Toolpaths are optimized for HSM machining to prolong the life of the tool

For more information about SprutCAM Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884