Tolerance Based Machining (TBM) with CAMWorks

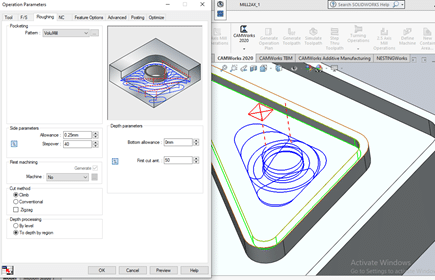

In addition to CAMWorks AFR for identifying manufacturing features and automating the creation of tool paths. In addition, CAMWorks introduced features for recognizing dimensions, tolerances, and surface finish annotations associated with models. Camworks’ tolerance based machining can recognize Solidworks dimensions, tolerance ranges, and surface finish annotations to determine the appropriate machining strategy, tools, speeds, feeds, etc. to meet the specified tolerance and surface finish.

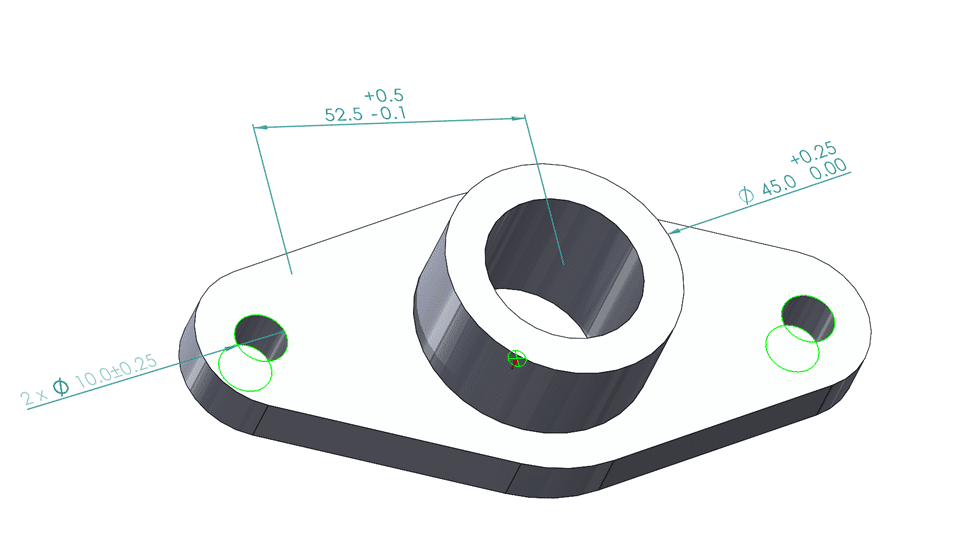

Solidworks MBD (Model-based definition), DIMXpert dimensions, and surface finish annotation can be utilized by designers in order to attach product and manufacturing information (PMI) such as tolerances and surface finish information directly to a 3D model.

CAMWorks TBM can automatically select the correct machine strategy for a given model based on the PMI data attached to the model, thereby increasing the automation of generating CAM data within CAMWorks.

Tolerance Range:

Based on the tolerances set in Solidworks, CAMWorks’ TBM setting selects specific machining strategies. Additionally, the machining depth cut, or tool motion will also be automated depending on the feature in order to achieve efficient production. The tolerance for these strategies may also be adjusted accordingly.

Machine to Mean:

CAMWorks TBM can also be configured to machine a feature within its mean tolerance dimensions when the upper and lower tolerance limits are taken into account.

Surface finish annotation.

The Multisurface feature in CAMWorks TBM settings allows you to choose the specific machining strategy according to the surface finish requirement. In these settings, tooling parameters such as speed and feed are automatically adjusted to achieve the desired surface finish.

The TBM feature of CAMWorks reduces the need for manual adjustments when machining the production. The application accounts for all the important parameters, including tolerances and surface finish.

For more information on CAMWorks Software and product enquiries, visit us at http://www.nctools.com.au/or call us on +61 3 8618 6884.