Introducing SprutCAM X 17 and SprutCAM X Robot 17: CAD/CAM/OLP for the Next Generation Makers

SprutCAM Tech has released updated versions of CAD/CAM/OLP software. SprutCAM X and SprutCAM X Robot version 17 are CAD/CAM systems designed for the next generation of makers. They are the most powerful and functional versions to date but at the same time easy to learn and use. The new version introduces innovations and key features, including Éncy, the first virtual AI assistant in the CAD/CAM

CAM programs for CNC machines – Why CAMWorks stands out from the competition

CAM programs for CNC machines - Why CAMWorks stands out from the competition CAM (Computer-Aided Manufacturing) program is an essential tool in CNC (Computer Numerical Control) machining. In order to manufacture a part or product, they create the toolpath that

7 Tips for Laser Cutting Cost Calculations

Accurate laser-cutting cost calculations are crucial for businesses in the manufacturing industry. Understanding the importance of these calculations is essential for optimizing production processes, managing costs effectively, and ensuring profitability. Material and Thickness Requirements Different materials have varying properties and react differently

Transforming Hollow Metal Door Frame Design with Smart Technology

Transforming Hollow Metal Door Frame Design with Smart Technology Increasing efficiency and reducing costs in manufacturing is often driven by innovation. Some industries, however, have been slower to adopt cutting-edge technology. Hollow metal door frames are traditionally designed using manual and

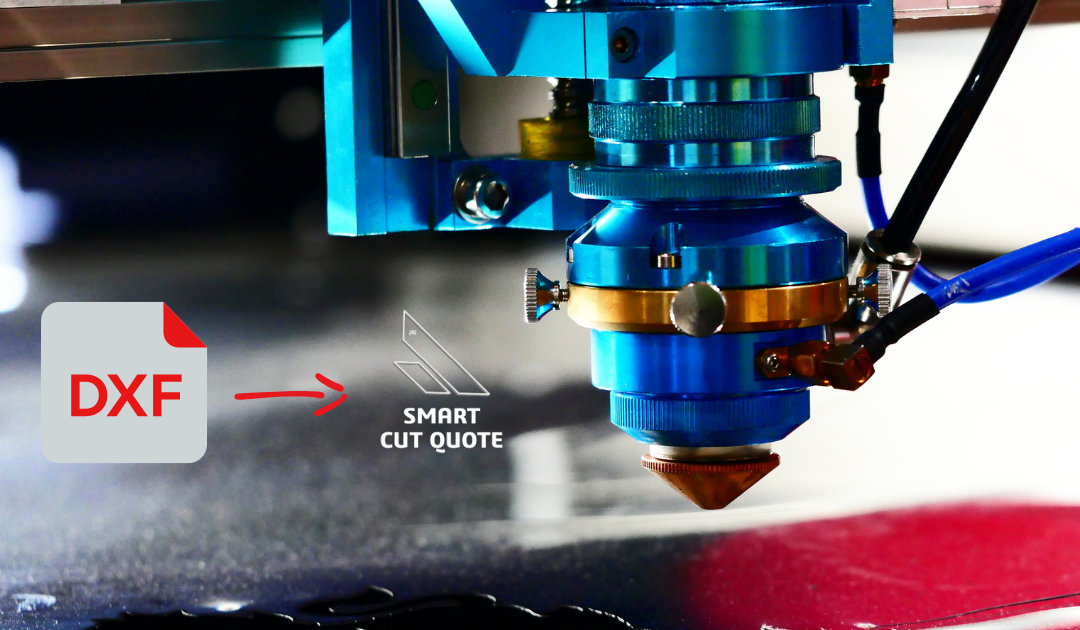

DXF to Quote: Streamlining Estimations with Modern Software Tools

DXF to Quote: Streamlining Estimations with Modern Software Tools Digital Exchange Format, commonly known as DXF, has become a standard in the design and manufacturing industry. Originated by Autodesk as a format for AutoCAD, DXF files serve as a bridge to

SprutCAM X17 Now Released in Australia & New Zealand

We're thrilled to introduce the all-new SprutCAM X17, a cutting-edge advancement in the world of CAD CAM technology. Tailored for today's innovative creators, this version stands out in its commitment to precision and streamlined production. SprutCAM X17 is enhanced in numerous

Fiber Laser Safety: Essential Tips for Preventing Accidents and Ensuring Operator Well-being

Fiber Laser Safety: As with any piece of machinery that uses lasers, fiber lasers need to be operated with great care to prevent accidents and ensure the safety of the operator and others around him. If you are planning on using

Smart Cut Quote: Elevating Laser Cutting with Rapid, Accurate Quotes

Keeping a competitive edge in the laser machining industry requires a revolutionary tool such as Smart Cut Quote software. The system offers a rapid, precise response to the industry's need for laser machine quotes, revolutionizing the way it generates them.

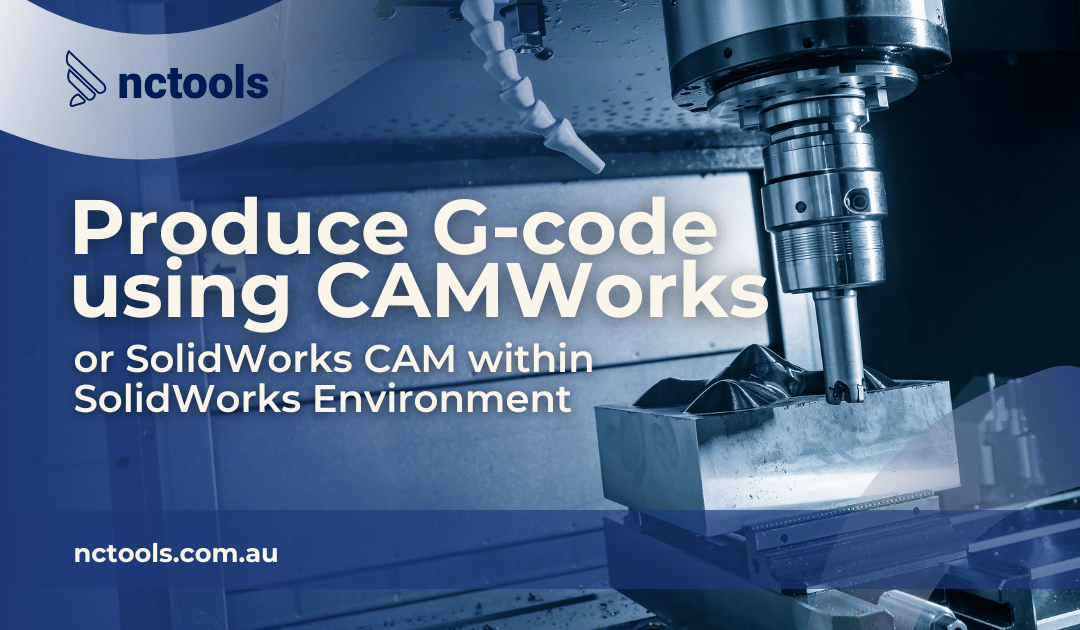

To efficiently produce G-code using CAMWorks or SolidWorks CAM within the SolidWorks environment, proceed with the following steps:

To successfully generate G-code in SolidWorks using CAMWorks or SolidWorks CAM , follow these tailored instructions: Initiate Your Project: Start by opening your SolidWorks application. Select the part or assembly you plan to work on, ensuring it's fully designed and

Unveiling CAMWorks 2024: The Pinnacle of CNC Programming Innovation

Unveiling CAMWorks 2024: The Pinnacle of CNC Programming Innovation CAMWorks 2024 marks a significant milestone, bringing a suite of new features and enhancements that revolutionise CNC programming. Let's explore the cutting-edge developments CAMWorks 2024 presents to the industry. Refined Probing Cycles and