NestingWorks: The Seamless Nesting Solution Inside SOLIDWORKS

NestingWorks: The Seamless Nesting Solution Inside SOLIDWORKS

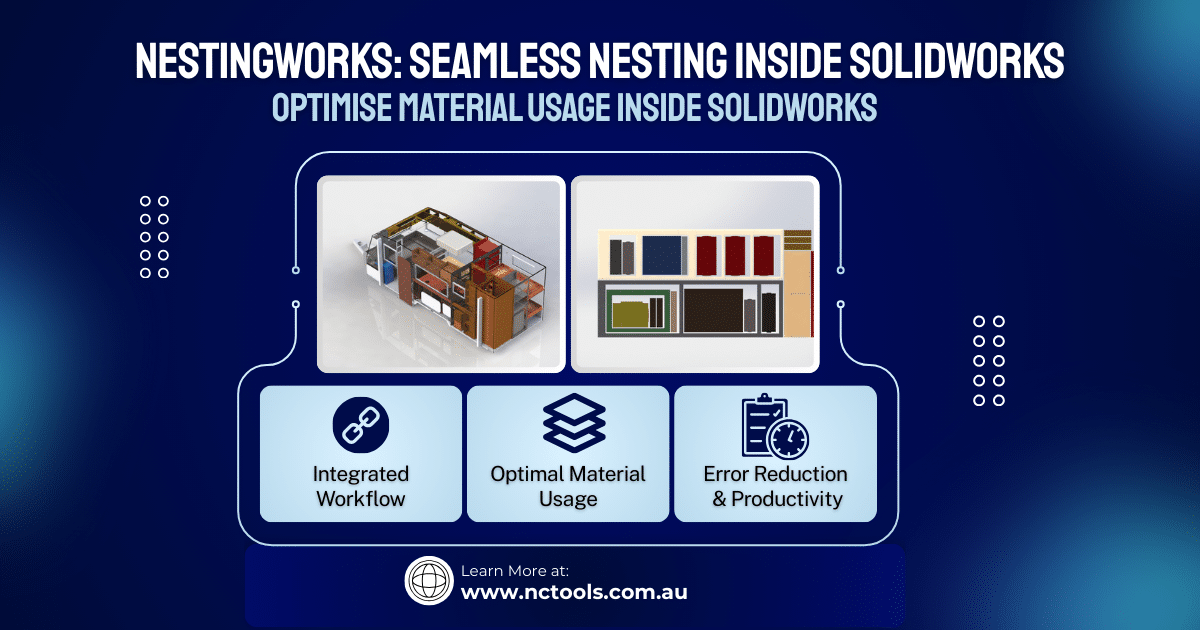

NestingWorks is a powerful nesting software solution fully integrated within SOLIDWORKS. Designed to simplify and optimise the process of arranging parts on raw materials, it enables manufacturers to maximise material usage and reduce waste directly within their familiar CAD environment. By leveraging the intuitive interface of SOLIDWORKS, NestingWorks offers a seamless and efficient workflow for design-to-manufacturing processes.

What Makes NestingWorks Stand Out?

NestingWorks stands apart due to its robust feature set and deep integration with SOLIDWORKS. Here’s why it’s a preferred choice for manufacturers:

- Fully Integrated Workflow:

Unlike standalone nesting software, NestingWorks operates entirely within SOLIDWORKS, eliminating the need to export and import data between applications. This integration ensures that users can quickly transition from design to nesting without additional steps. - Associativity with SOLIDWORKS Models:

Changes made to the original design in SOLIDWORKS are automatically reflected in the nested layouts, maintaining accuracy and consistency throughout the process. This feature is crucial for managing design iterations efficiently. - Optimal Material Utilisation:

NestingWorks employs advanced algorithms to optimise part layouts, minimising material waste. It considers part shapes, material grain direction, and other constraints to generate the most efficient nesting patterns. - Ease of Use:

NestingWorks’ interface is designed with simplicity in mind, making it accessible to both novice and experienced users. Its intuitive setup allows users to define nesting parameters and generate layouts in just a few clicks. - Support for Complex Designs:

Whether dealing with intricate part geometries or multiple material types, NestingWorks handles complexity with ease, providing reliable and precise nesting solutions.

How NestingWorks Benefits Manufacturers

- Reduced Material Costs: By maximising material usage, manufacturers save on raw material expenses, making operations more cost-effective.

- Time Savings: Automated nesting eliminates the time-consuming task of manually arranging parts, accelerating the manufacturing workflow.

- Error Reduction: The direct associativity with SOLIDWORKS models reduces errors caused by manual data transfers or design changes.

- Enhanced Productivity: With streamlined processes and optimised layouts, manufacturers can handle more projects in less time.

Applications Across Industries

NestingWorks is ideal for industries that rely on sheet cutting processes, including sheet metal fabrication, woodworking, and plastics manufacturing. Its flexibility and scalability make it suitable for businesses of all sizes, from small workshops to large-scale manufacturing facilities.

Why Choose NestingWorks?

For SOLIDWORKS users, NestingWorks offers an unmatched combination of convenience, precision, and efficiency. By integrating directly into the design process, it removes barriers between CAD and CAM workflows, allowing manufacturers to focus on delivering high-quality products while minimising waste and costs.

NestingWorks is more than just a nesting solution—it’s a key tool for driving productivity and profitability in modern manufacturing.

For more information on CAMWorks Software and product enquiries visit us at https://nctools.com.au/ or call us on +61 3 8618 6884