Estimate-laser-cutting-jobs-in-seconds-how-laser-quoting-software-speeds-up-the-estimating-process

Estimate-laser-cutting-jobs-in-seconds- Precision and efficiency have never been so high in the manufacturing and fabrication industry as they are today, thanks to laser cutting. An important aspect of laser cutting is estimating the time needed for each job, a task that was traditionally labour-intensive and time-consuming. In recent years, laser quoting software has simplified this process, accelerating estimating and improving overall operational efficiency.

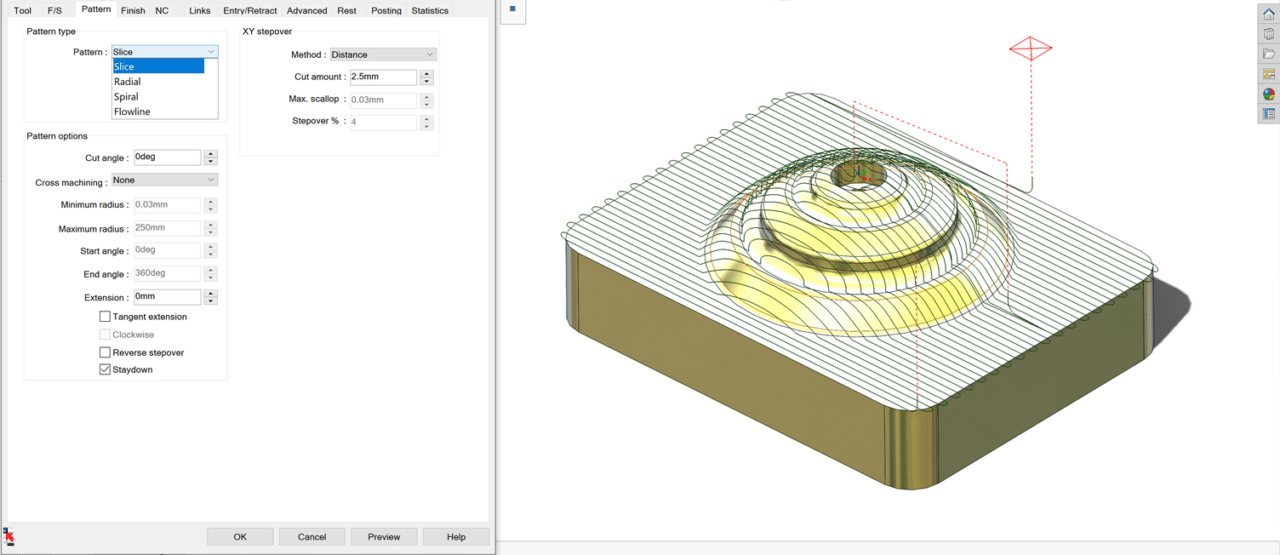

The laser quoting software uses advanced algorithms and parameters to quickly estimate the time required for laser cutting jobs. Software takes into account various factors, including material type, thickness, design complexity, machine power, and cutting speed. It is possible to quickly generate accurate estimates using these parameters by entering them into the software, often in a matter of seconds. Compared to manual estimation methods, which could take hours or even days, this is a vast improvement.

Laser quoting software can access a wealth of material properties and cutting parameters, which explains its speed. As a result of this database being continually updated, the software stays current with the latest advances in laser cutting technology. Through this process, the software can quickly analyse the job requirements and retrieve optimal cutting settings, which reduces trial-and-error time.

In addition to its user-friendly interface, laser quoting software contributes to its efficiency. As manufacturers and fabricators input job specifications, the software guides them through the process, prompting them for necessary details. This minimizes the possibility of errors and ensures that all crucial parameters are considered when estimating. In mere seconds, the software’s algorithms process the data and provide an accurate estimate once the input is complete.

Laser quoting software offers more benefits than just time savings. Rapid estimates enable manufacturers to respond quickly to customer inquiries and requests for quotes. As a result, customers are more likely to be satisfied and orders are more likely to be secured. Furthermore, the accuracy of the estimates contributes to better resource allocation, reduced waste, and optimal machine utilization.

By simplifying the estimating process, laser quoting software has revolutionized the laser cutting industry. By analyzing job parameters quickly and accessing a comprehensive database of cutting settings, the software generates accurate estimates in seconds. As a result of this efficiency, not only do customers get a better service but also resources are more effectively managed. Manufacturing and fabrication processes will become increasingly optimized as technology advances. Laser quoting software will likely play an increasingly important role.

Smart Cut Quote is an innovative laser quoting software that transforms the estimation process. With its advanced algorithms and comprehensive database, it calculates laser cutting job estimates quickly and accurately. Modern manufacturing and fabrication benefit from its user-friendly interface, which makes it a valuable tool.

For more information about SmartQuote Software and other product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884

More Info can be found here https://smartcutquote.com/