CADCAM software is essential for modern CNC shops

CAD

The design phase is the beginning of any manufacturing process. If you do not have a CAD model design, manufacturing a part will be very difficult or we might say that it is not efficient to carry out the production process without a CAD model design. A computer-aided design process (CAD) is the use of computers to create, modify, analyze, function, or apply a design, which replaces manual drafting with a more automated process. CAD software enables companies to increase their productivity and improve the quality of their designs.

CAM

CAM is an acronym for computer-aided manufacturing. The CNC machine can be operated with the assistance of CAM software. A CAM program is used to generate toolpaths and to control CNC machines like lathes, mills, etc. with G-code. Traditionally, this was done by hand. However, CAM systems automate this process by converting digital models into detailed manufacturing instructions. A CAM program is used to design machining processes using 3D models. Thus, without Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM) would not be possible.

CAD-CAM in manufacturing offers the following benefits:

Almost every manufacturing industry now uses some kind of CAD-CAM system to manage its operations. Among the benefits of CAD-CAM systems are:

- Enhances machining capabilities

Manufacturers can improve their machining capabilities by using a CAD/CAM system.

- Accelerate delivery times

Manufacturers can receive CAD files from their customers using CAD-CAM software. Upon receiving these files, they can specify the machining tool path, perform simulations, and calculate machining cycle times. The result is more rapid delivery of products to the market.

- Improves the productivity of CNC machines

CAD-CAM systems provide high-speed machine toolpaths to enhance cutting accuracy and quality. Using high-speed machining improves the productivity of a CNC machine.

- Helps to reduce material waste

By using simulation features in CAD-CAM software, manufacturers can visually inspect the machining process to avoid mistakes and reduce material waste.

Why CAMWorks?

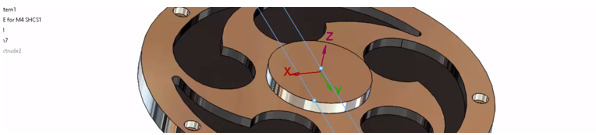

CAMWorks is a feature-based parametric machining program. By utilizing the latest technologies and adaptive automation tools for CNC machining, advanced CAD/CAM software can increase productivity. It is fully integrated with CAD systems, such as SolidWorks. Due to this integration, you can use the same graphical user interface and solid models for design and later to simulate machining.

CAMWorks software offers the following advantages:

- Automated Feature Recognition eliminates hours of complex programming.

- Automatically adjusts the part model to accommodate changes.

- Eliminate time-consuming CAM system rework resulting from design modifications.

- Automatically generates accurate toolpaths with the click of a button.

- Enhances machining productivity.