Can You Afford to Lose Material with Inefficient Nesting?

Can You Afford to Lose Material with Inefficient Nesting? Comparing Cypcut with MAXXCAM

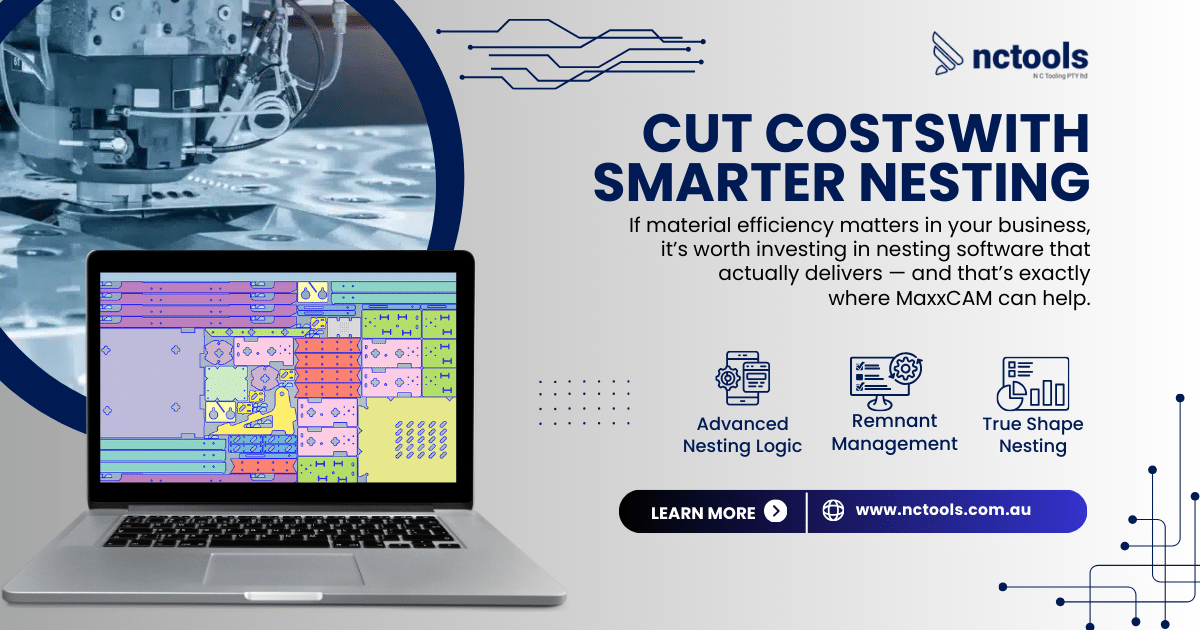

Chinese fibre laser machines, often bundled with free software like Cypcut, offer a cost-effective entry into the laser cutting market. While these machines get the job done, the efficiency of the software they come with—particularly in nesting capabilities—often leaves room for improvement. MAXXCAM, a leading European product, provides a powerful alternative that optimises material usage and maximises cost savings.

Why Nesting Efficiency Matters

Inefficient nesting can have significant repercussions:

- Material Waste:

- Poor nesting results in higher scrap material, increasing costs over time.

- Production Delays:

- Ineffective layouts can require additional cuts, prolonging job completion times.

- Hidden Costs:

- The apparent savings from free software may be offset by long-term inefficiencies, material waste, and lost productivity.

Comparing Cypcut and MAXXCAM

| Feature | Cypcut | MAXXCAM |

|---|---|---|

| Nesting Algorithms | Basic, limited optimisation | Advanced, industry-leading precision |

| Material Utilisation | Higher scrap rates | Minimal waste, maximum efficiency |

| Processing Speed | Slower for complex jobs | High-speed, handles large batches |

| Customisation | Limited flexibility | Highly customisable for various needs |

| Multi-Sheet Nesting | Basic or unavailable | Comprehensive multi-sheet management |

| Machine Compatibility | Mostly Chinese machines | Compatible with diverse CNC setups |

| Sustainability | Limited focus on waste reduction | Designed for sustainable practices |

| Support and Updates | Minimal support and updates | Extensive support and regular updates |

Impact of Choosing MAXXCAM Over Cypcut

- Material Savings:

- MAXXCAM ensures more efficient layouts, reducing material costs significantly compared to Cypcut.

- Over time, the savings from reduced waste can exceed the cost of adopting premium software.

- Improved Productivity:

- Faster nesting and cutting processes allow for quicker job completions.

- High-precision layouts reduce rework and downtime.

- Cost Justification:

- While the machine is a one-time investment, material costs recur with every job. Investing in superior nesting software like MAXXCAM ensures long-term savings.

- Quality and Reputation:

- Consistently efficient production enhances quality, improves customer satisfaction, and bolsters your business reputation.

- Sustainability:

- By minimising waste, MAXXCAM aligns with eco-conscious practices, which can be a selling point for customers.

The Smart Decision: MAXXCAM for Superior Nesting

Now that you’ve saved money by choosing a cost-effective Chinese fibre laser machine, it makes sense to invest in a software solution that ensures you don’t lose money due to inefficient nesting. MAXXCAM offers:

- Advanced nesting algorithms for optimal material utilisation.

- Compatibility with machines from all manufacturers, including Chinese fibre lasers.

- Comprehensive support and training to help you get the most out of your investment.

Choosing Cypcut as a bundled solution might seem economical at first, but inefficiencies in nesting can lead to significant losses over time. With MAXXCAM, you unlock the full potential of your fibre laser machine, reducing waste, saving costs, and ensuring efficient production. The initial investment in powerful nesting software pays dividends in long-term savings, higher productivity, and better business outcomes. Don’t let cost savings on a machine be overshadowed by losses in material and time—choose MAXXCAM for precision and profitability.

\