How Nesting Algorithms Affect Material Use in Laser Cutting

How Nesting Algorithms Affect Material Use in Laser Cutting

In laser cutting, the quality of the nesting algorithm plays a major role in how much material you use — and ultimately how much you save. Good nesting can reduce waste, improve sheet utilisation, and lower the cost per part. Poor nesting, on the other hand, often leads to higher scrap rates and unnecessary material purchases.

What Nesting Actually Does

Nesting arranges your parts on the sheet in a way that minimises unused space. This sounds simple, but when parts vary in size or shape, and when grain direction or part rotation matters, the algorithm’s ability to make smart decisions becomes crucial.

Basic or entry-level nesting software (often bundled with lower-cost Chinese fibre lasers) tends to use simpler, faster methods that do not fully optimise for complex shapes or variable part sizes. These systems may also lack features like part priority, common-line cutting, or dynamic remnant tracking — which can make a big difference in real-world production.

Where MaxxCAM Stands Out

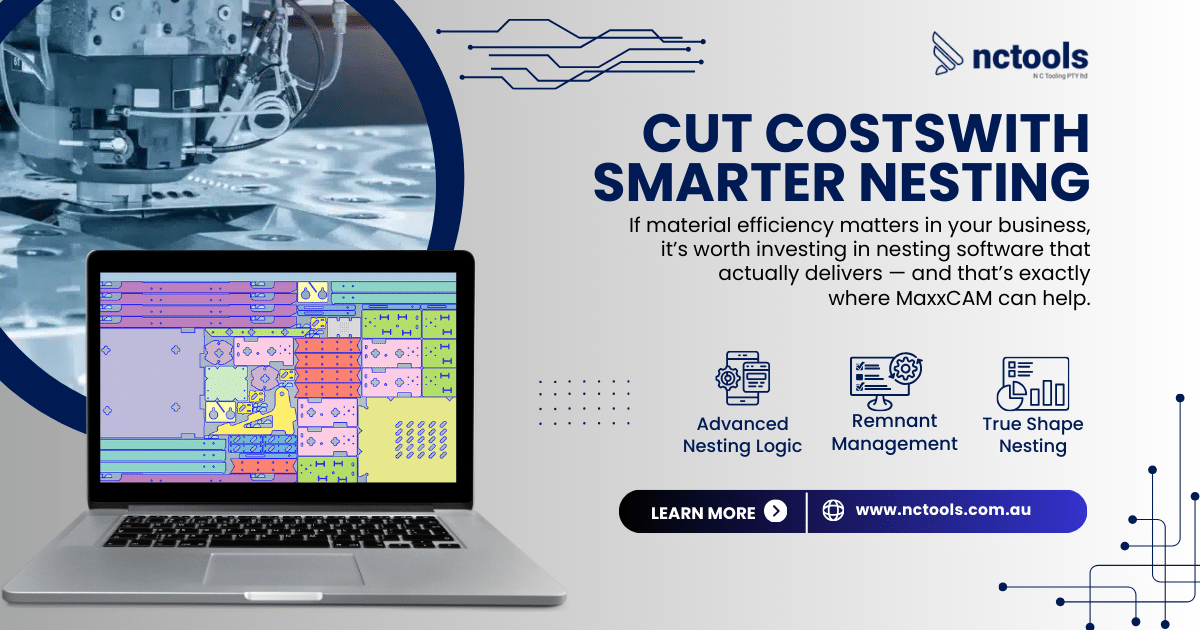

MaxxCAM includes a powerful, industry-grade nesting engine designed to maximise sheet usage with every job. Here’s how it compares:

- Advanced Nesting Logic

MaxxCAM goes beyond basic rectangular or static nesting. It dynamically evaluates part shapes, allows for tighter nesting, and can auto-rotate or flip parts where allowed. - Remnant Management

Automatically tracks leftover material and suggests where to use it in future jobs, reducing waste over time. - True Shape Nesting

Ideal for irregular parts, MaxxCAM ensures every contour is considered — not just bounding boxes. - Optimised for Speed and Material Saving

Balances computation speed with smart decision-making to give fast yet efficient nests for production. - Real-time Feedback

Get instant updates on utilisation percentage, cut time, and material requirements — which helps with quoting and planning.

Compared to generic nesting tools supplied with many Chinese fibre lasers, MaxxCAM offers more control, better accuracy, and long-term savings — especially important if you’re cutting varied or high-volume parts.

If material efficiency matters in your business, it’s worth investing in nesting software that actually delivers — and that’s exactly where MaxxCAM can help.

For further information on MaxxCAM software and product inquiries, visit us at https://nctools.com.au/ or contact us at +61 3 8618 6884.