WHAT DO YOU KNOW ABOUT CAMWORKS?

KNOW ABOUT CAMWORKS?- CAMWorks is the first CAM software product to be certified as a SolidWorks Gold product. CAMWorks is an integrated CAD/CAM solution for CNC machines. It could also be said that CAMWorks bridges the manufacturing process of CNC machines and Solidworks. In addition to reducing programming time, it increases productivity and improves the quality of CNC machined parts.

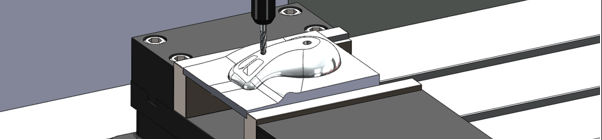

As a parametric, feature-based system, CAMWorks allows the machining of 3D machined parts inside the Solidworks environment. It creates smart programs for CNC machines. Creating a tool path in CAD/CAM is a time-consuming process. CAMWorks provides an efficient solution to this problem.It extracts the geometry of the part and generates the digital programming code which controls the machine and manipulates the tooling to produce the custom-designed part. The user can setup a “Feature Tree” to organize workflow, set tool paths, and run cutting simulations before the machine does any actual cutting. CAMWorks offers a wide range of features and functions. For instance, simulation is one of the tools that help eliminate errors through visual inspection. NestingWorks automatically nests layouts of parts and assemblies within CAMWorks.

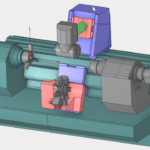

The post-processor converts toolpath information into code. The tool path is automatically updated when the user makes changes to the design. Associability saves much time. After the post-processing step has been completed, the programming code is ready to run on the machine. The CAD and CAM systems are saved as a single file. Consequently, files can be managed very easily in CAMWorks. The Volumill from CAMWorks reduces machining time by up to 85% while increasing tool life by up to 500% even when machining the hardest materials. CAMWorks machining modules include the following:

> 2.5 axis, 3 axis, 4 and 5 axis prepositioning

> 4 and 5 axis Simultaneous Milling

> 2 and 4 axis Turning

> Mill-Turning Machining

> Rotary Milling

> 2 and 4 axis Wire EDM