Top Benefits of Integrating CAD and CAM Software

Top Benefits of Integrating CAD and CAM Software

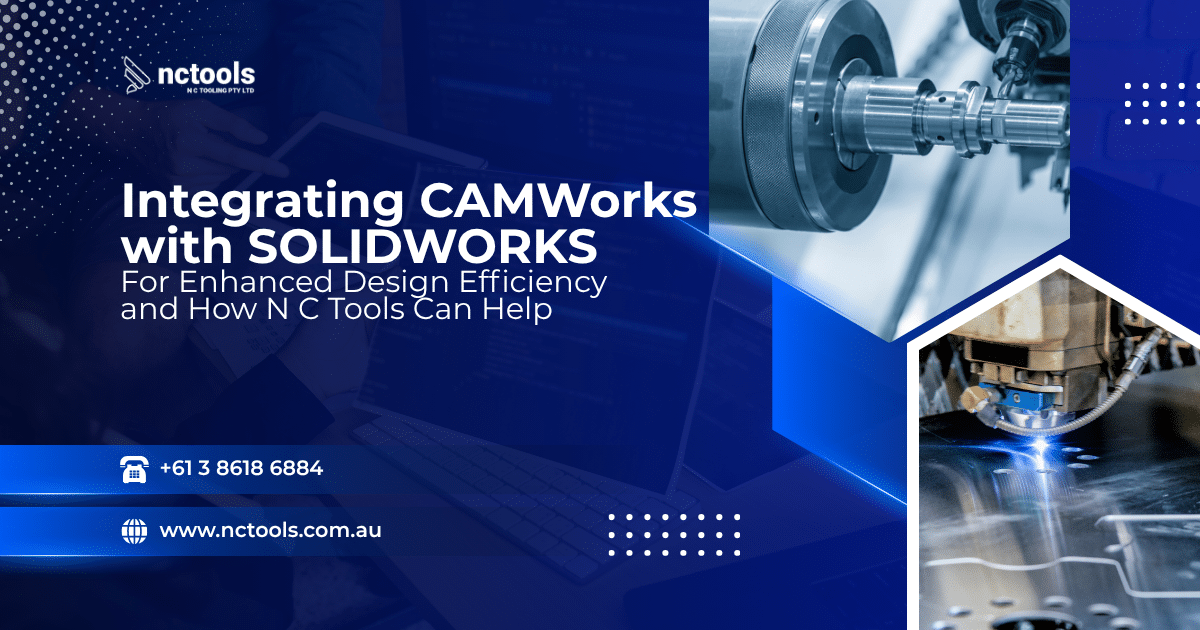

Manufacturers working with CNC machining often experience inefficiencies when transitioning from design to production. Traditional workflows require exporting CAD files to a separate CAM system, increasing the risk of data translation errors and making programming more time-consuming. Integrating CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software ensures a seamless connection between design and machining. CAMWorks and SOLIDWORKS CAM are fully integrated inside SOLIDWORKS, allowing users to program toolpaths directly within the design environment. As the first Gold Partner CAM solution for SOLIDWORKS, CAMWorks enables a fully associative workflow between CAD and CAM, reducing errors, improving efficiency, and streamlining the entire process.

Seamless Transition from Design to Machining

Using CAM software within SOLIDWORKS eliminates the need for exporting, converting, or working with separate applications. CAMWorks and SOLIDWORKS CAM allow users to generate toolpaths within the SOLIDWORKS environment, ensuring that the original design data remains unchanged. This approach helps maintain design accuracy and ensures machining strategies align with the intended part geometry.

Reducing Programming Time with Feature-Based Machining

Manually defining toolpaths for every part feature can slow down production. CAMWorks and SOLIDWORKS CAM incorporate Feature-Based Machining (FBM), which automatically detects machinable features such as pockets, holes, and profiles. By applying predefined machining strategies, FBM reduces programming time while maintaining consistency. This automation is particularly useful for manufacturers working on repetitive components or batch production, where efficiency is critical.

Automatic Tool Path Updates for Design Changes

When design modifications occur, manually updating toolpaths can lead to delays and mistakes. Since CAMWorks and SOLIDWORKS CAM are fully associative with SOLIDWORKS, any changes made to the CAD model are automatically reflected in the CAM setup. This eliminates the need for reprogramming, reduces the risk of machining outdated versions, and ensures design revisions are incorporated seamlessly.

Optimized Toolpath Strategies for Efficiency

An integrated CAM solution provides access to advanced toolpath strategies that improve machining efficiency. CAMWorks supports high-speed machining, adaptive clearing, and multi-axis cutting, which helps reduce cycle times while extending tool life. Simulation tools allow users to verify toolpaths before machining, minimizing errors and preventing costly material wastage.

Enhanced Collaboration Between Design and Production Teams

Using standalone CAM software often results in miscommunication between design and manufacturing teams. With an integrated solution, engineers and machinists can work within the same SOLIDWORKS environment, reviewing designs and machining parameters without the need for external software. This setup ensures that production teams receive accurate machining data while enabling real-time feedback from manufacturing engineers.

Standardizing Machining Processes with Knowledge-Based Machining

CAMWorks features Knowledge-Based Machining (KBM), which allows users to store machining strategies and apply them to similar parts. This helps standardize machining processes across different jobs, reducing variability and ensuring that best practices are consistently followed. Automating these strategies also minimizes manual input, improving efficiency while maintaining quality.

Handling Complex Machining Requirements

For manufacturers working with 3-axis, 4-axis, and 5-axis machining, an integrated solution like CAMWorks provides advanced programming capabilities for complex geometries. With multi-axis toolpaths, automated feature recognition, and efficient roughing strategies, CAMWorks is widely used in industries requiring high-precision machining, such as aerospace, automotive, and medical device manufacturing.

Flexible Integration Capabilities Through API

While CAMWorks does not include direct MRP integration, it offers API support, allowing businesses to develop custom integrations. With SOLIDWORKS’ API and CAMWorks’ capabilities, manufacturers can connect their CAD/CAM system with MRP, ERP, and other production management software as needed. This flexibility enables businesses to streamline data exchange and automate workflows based on their specific requirements.

By leveraging an integrated CAD/CAM environment with CAMWorks and SOLIDWORKS CAM, manufacturers can enhance productivity, improve accuracy, and eliminate redundant tasks. With direct tool path programming inside SOLIDWORKS, feature-based automation, and flexible API-driven integration options, businesses can optimize their machining processes while maintaining a connected and efficient workflow.

For more information on CAMWorks Software and product enquiries visit us at https://nctools.com.au/ or call us on +61 3 8618 6884