Wire EDM:

1.Automatic Solid to G-Code in a Single Mouse Click!

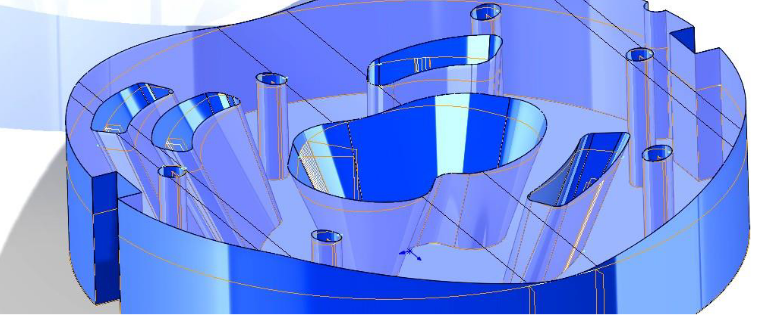

CAMWorks WireEDM Pro is seamlessly integrated with SOLIDWORKS/CAMWorks Solids and is designed to automatically analyze a selected solid model, generate a machining plan for all its features (2 Axis, 2 Axis Taper, 4 Axis) and then post the G-Code with a single mouse click!

2.Automatic Feature Recognition Technology

The Automatic Feature Recognition functionality has evolved to recognize EDM features such as 2 Axis, 2 Axis with taper and both synchronized and unsynchronized 4 axis features present on a solid model. This highly advanced functionality virtually eliminates the requirement of several 2D sketches for defining the top and bottom cuts. Even the requirement for presence of a planar surface is a thing of the past. Additionally, the ability to automatically program from a 2D wire frame still exists. This option gives you control when you need it and saves time when you do not.

3.Accurate Post Processing

The Post processors shipped with the CAMWorks Wire EDM Pro application are the result of years of continuous collaboration with machine experts, thereby ensuring that the G-code generated using these post processors is as machine ready as possible.

4.Customized Post Processing

The default post processors shipped with the CAMWorks Wire EDM Pro application will accommodate most of your WireEDM machining needs. However, for specific situations where formatting may mandate changes, Geometric Americas, Inc. also offers customization services for post processors. Such customized post processors ensure that the G-code generated using the CAMWorks Wire EDM Pro application will be a perfect match for running on the intended Wire EDM machines.

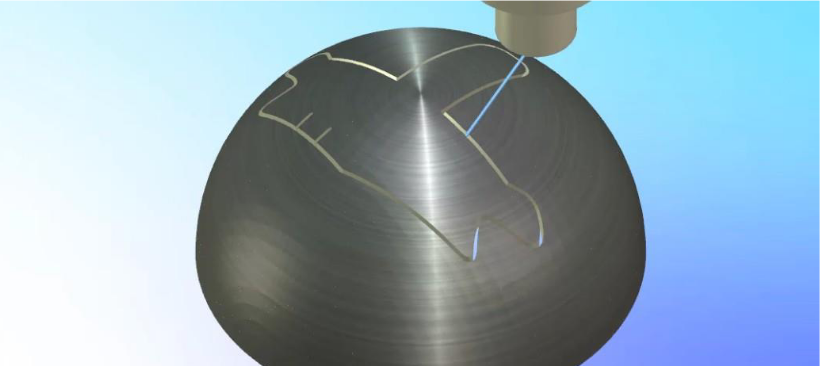

5.Powerful SimulationCAMWorks

WireEDM Pro also features powerful simulation powered by Predator Virtual CNC. This feature allows you to verify tool path accuracy, potential collisions, and machining order before taking the G-code to the Wire EDM machine. Streamline your design and planning process with this powerful aid for simulating WIP models.

6.Intuitive User Interface with Customization Options

The color-coded strategies available within the CAMWorks WireEDM Pro user interface allow you to customize your machining processes and user technology. Apply the corresponding color and CAMWorks WireEDM Pro will identify the strategy or surface finish and apply it to the colored features, thereby minimizing verification time required for error checks.

7.Support for AgieVision and HMI2 Posting

CAMWorks WireEDM Pro fully supports Agie Vision and HMI2 posting. CAMWorks WireEDM Pro can take you from the solid model to generating toolpath and then to automatically loading all the incorporated files straight on to the Agie Vision control with one single click. CAMWorks WireEDM Pro application’s support of GF machines is so complete that it is the first CAM system to receive an endorsement by the manufacturer itself.

8.Cutting Conditions Database

The knowledge-based machining technology, tooling details, cutting conditions and operation defaults saved in the Technology Database are used to generate machining operations and toolpaths automatically. Such a repository ensures uniformity and quality in the generated toolpaths. The intelligence behind the machining automation in CAMWorks Wire EDM Pro application is a database of Cutting Conditions. This database is shipped with data that is considered generally applicable to most Wire EDM machining environments. It enables computation of tool paths based on standard or customized cutting conditions defined in the database. The finish and tolerance can be assigned, edited and simulated before generating the G-code. This allows you to save time while using your WireEDM machine to its full potential.

9.List of Features/Functionalities in CAMWorks Wire EDMPro

•Automatic Solid to G-Code in one mouse click

•Automatic Feature Recognition of 2 Axis, 2 Axis Taper, and 4 Axis Features on the solid model

•Full Agie Vision and HMI2 support, and Agie Vision integration•Automatic/ Manual adjustment of Feature Level Control

•Automatic / Manual Glue Stops, up to 8 stops per shape

•Automatic calculation of Lead-ins and Lead-outs

•Automatic calculation of start holes

•Automatic Wire Threading support

•Automatic/Manual Land and Taper Function(Part&Feature levels)

•Automatic Start Holes from solid model

•Output of Start Hole Program for EDM hole making machine or CNC Mill

•Definable Corner Types

•Definable number of Skim Passes up to 12

•Definable Work Plane and Program Plane

•Definable feature level automation

•Definable Post Attributes for each Feature

•Definable Stop Types

•Stock or Feature Machining Height

•Sub-routine support

•Independent Post Processing Order options for Punch and Die

•User Comments

•Display posted output in Edit Dialog

•Machine manufacturer-based Cutting Conditions Database •Cutting Conditions Database