Laser technology in sheet metal fabrication: benefits and applications

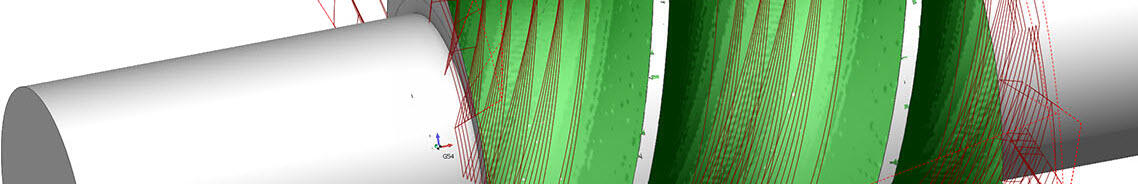

Manufacturing operations require cutting operations in order to fabricate parts. Metal fabricators use a variety of methods to cut metal, but laser cutting is one of the most advanced methods. The laser cutting process is a thermal-based, non-contact process capable of cutting complex contours on materials with a high degree of precision and accuracy.

Sheet metal fabrication can benefit from laser cutting in the following ways:

- Lasers are more efficient than blades when it comes to cutting.

- The metal sheet is not in physical contact with the Laser beam.

- When metal is cut with laser technology, there is little or no warping.

- Laser equipment can be quickly set up in order to increase productivity.

- Laser cutting generally results in a reduced amount of scrap material.

- Laser cutting produces clean edges on metal.

- There is no need to cover the cost of tooling when laser cutting is used.

- Laser cutting provides high levels of customization of products/Parts.

- Higher cutting precision and tighter tolerances than other methods.

The use of this cutting method is not surprising because it is widely used in manufacturing parts and components for the automotive and aerospace industries, dies, molds, and tools, household appliances and kitchenware, agricultural and construction machinery equipment, medical components, gymnastic equipment, and so much more.

There is, however, a problem with the quotation process in these metalworking industries. Various variables can affect the cost of a project in the metalworking industry, making quoting a challenge. Quoting is an important aspect of any business, but it is especially important for metalworking companies. Estimating the cost of a project is challenging because there are so many variables to consider, including materials, labour, and engineering. This industry requires metalworkers to be able to provide accurate quotes in a timely manner.

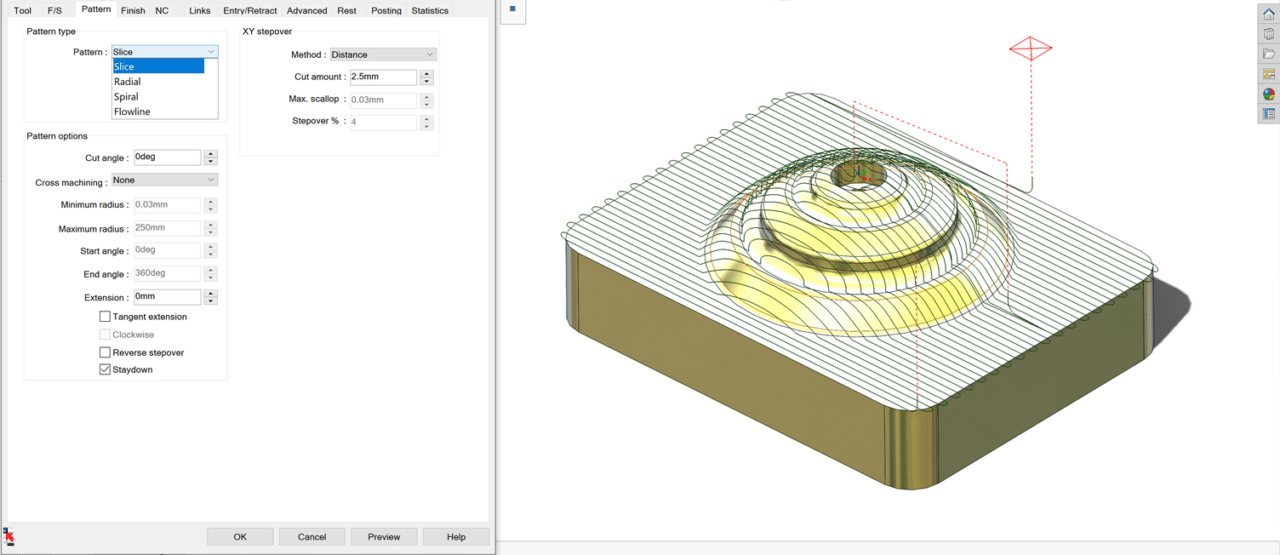

A smart cut quote is the most efficient and effective method for simplifying quotations and making them more efficient. The time it takes to generate quotes has been reduced from hours to minutes. Using the software, a quote can be generated automatically based on a customer’s specifications.

For more information about SmartQuote Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884