CAM programs for CNC machines – Why CAMWorks stands out from the competition

CAM programs for CNC machines – Why CAMWorks stands out from the competition

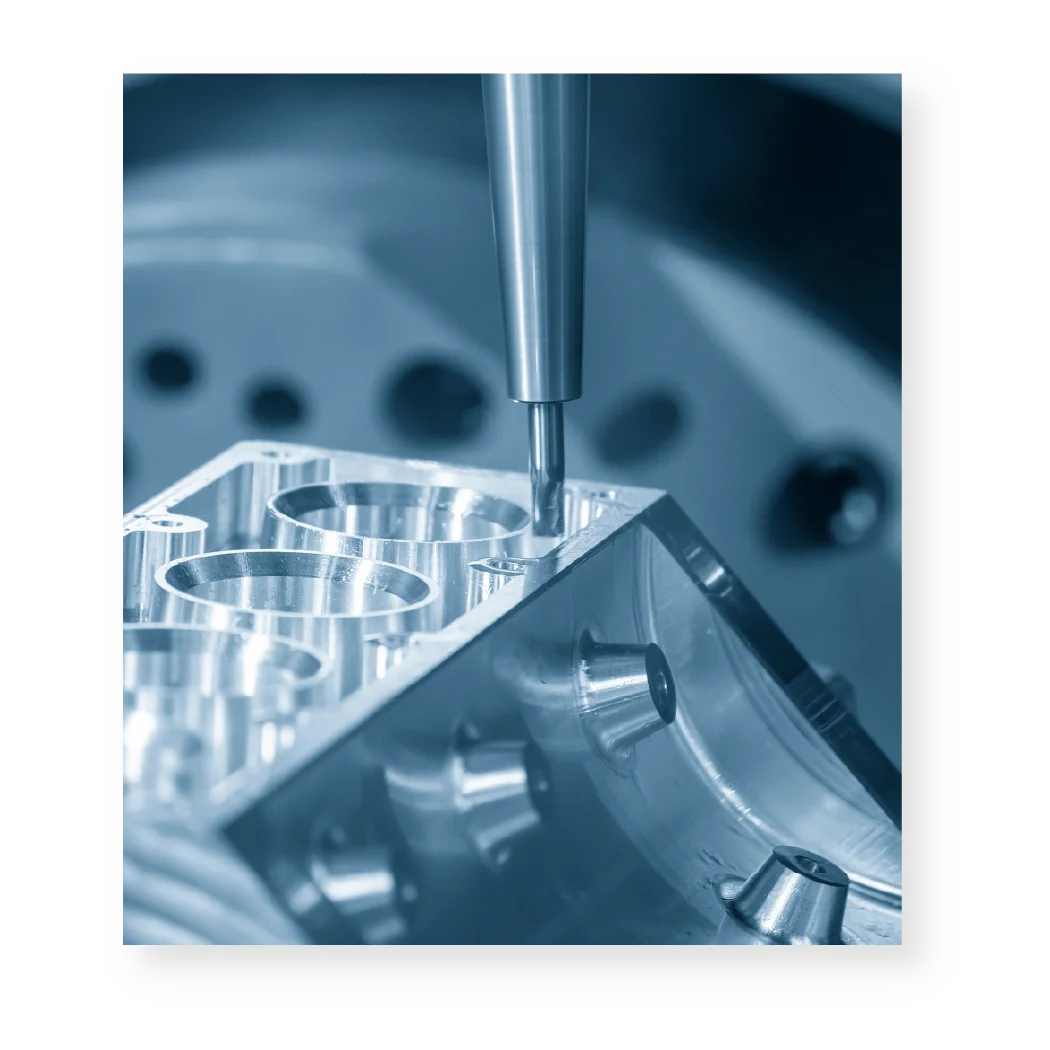

CAM (Computer-Aided Manufacturing) program is an essential tool in CNC (Computer Numerical Control) machining. In order to manufacture a part or product, they create the toolpath that a CNC machine will follow. One of the best CAM programs available is CAMWorks, which stands out among the others.

A fully integrated CAM system, CAMWorks, runs within SOLIDWORKS, a popular CAD (Computer-Aided Design) program. A feature-based approach is used to generate toolpaths that are optimized for the CNC machine and material being used. With CAMWorks, you can operate a wide variety of CNC machines, including mills, lathes, and wire EDM machines.

CAMWorks’ ease of use is one of the reasons for its popularity. The software’s user interface is intuitive, and it is designed to be easy to use. Consequently, even novice CNC machinists can use the software without extensive training. CAMWorks also provides a comprehensive library of machining strategies that cover a wide range of manufacturing processes.

Additionally, CAMWorks provides advanced functionality for optimizing toolpaths. By automatically detecting collisions between the tool and the workpiece, the CNC machine and the part being machined can be protected from damage. The program may also be used to optimize cutting parameters in order to reduce machining time and increase tool life. As a result, the manufacturing process becomes more efficient and production costs are reduced.

The seamless integration of CAMWorks with SOLIDWORKS is another major advantage of the software. As a result of this integration, users are able to create 3D models as well as generate toolpaths within the same software application. Furthermore, it facilitates easy modification of designs and toolpaths without the need for external file conversions. As a result, manufacturing processes become more efficient and errors are reduced.

There are many CAM programs available in the market today for CNC machining, but CAMWorks stands out as one of the most effective. Its user-friendly interface, comprehensive library of machining strategies, advanced functionality for optimizing toolpaths, and seamless integration with SOLIDWORKS make it an excellent choice for CNC operators. By improving the efficiency of the manufacturing process, reducing production costs, and ensuring that high-quality parts are consistently produced, the manufacturing process becomes more efficient.

For more information about CAMWorks Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884