SprutCAM is a great solution for quick programming and cost-effective machining. It brings you some better features and options among all CAM software.

Using SprutCAM, we can program a double-ended lathe part machining with a single chuck.

This can be done in three simple steps,

- Machine and workpiece setup

- Turn the first end

- Stop-flip the part and turn the second end

Machine and Workpiece Setup

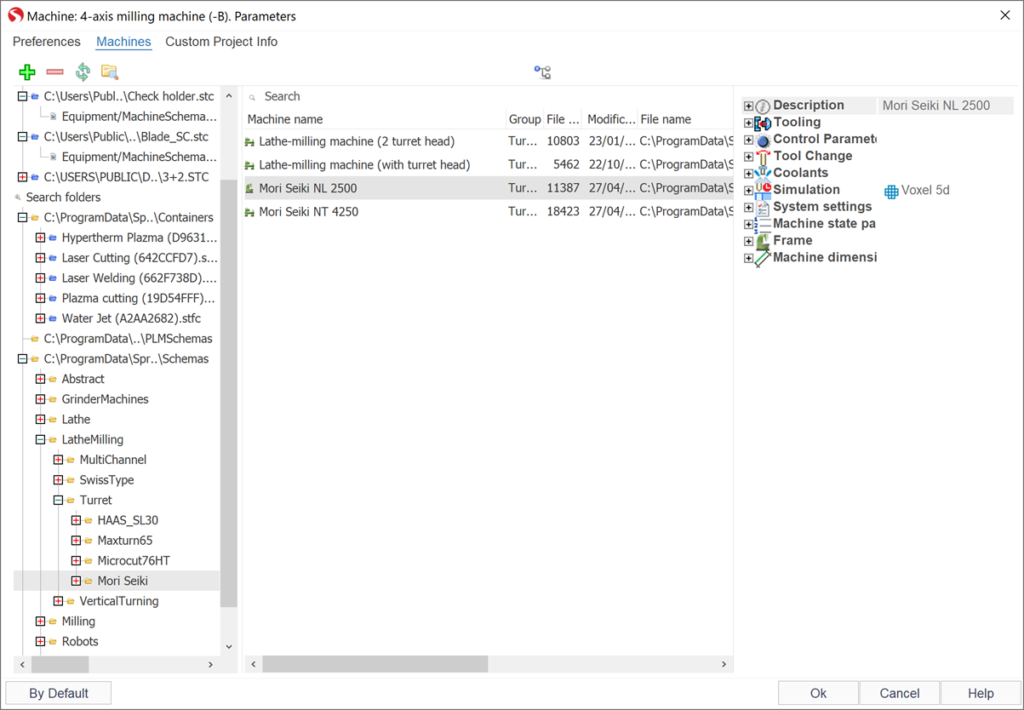

Select the suitable turning machine from the machine database. Preferably Mori Seiki NL 2500 for the below part (example) we used.

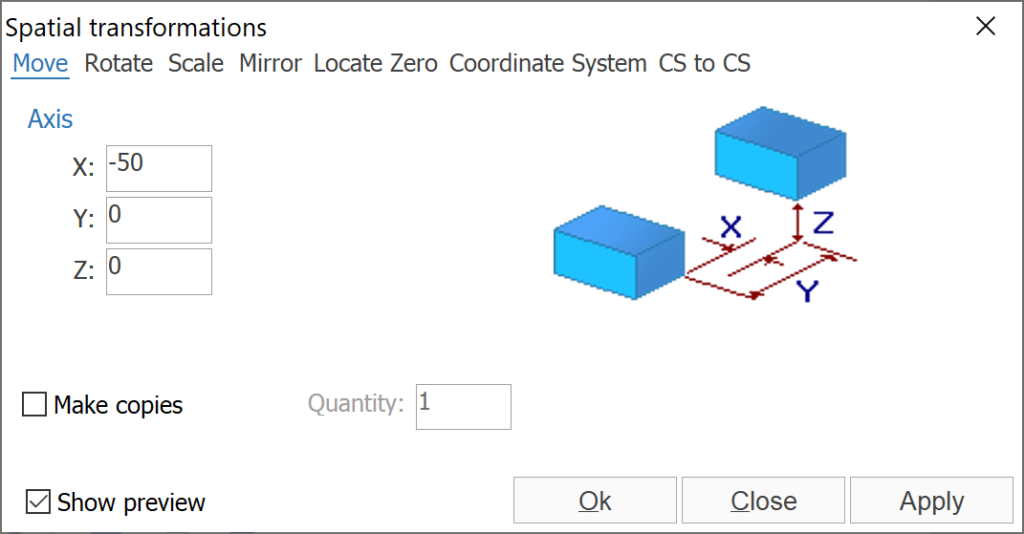

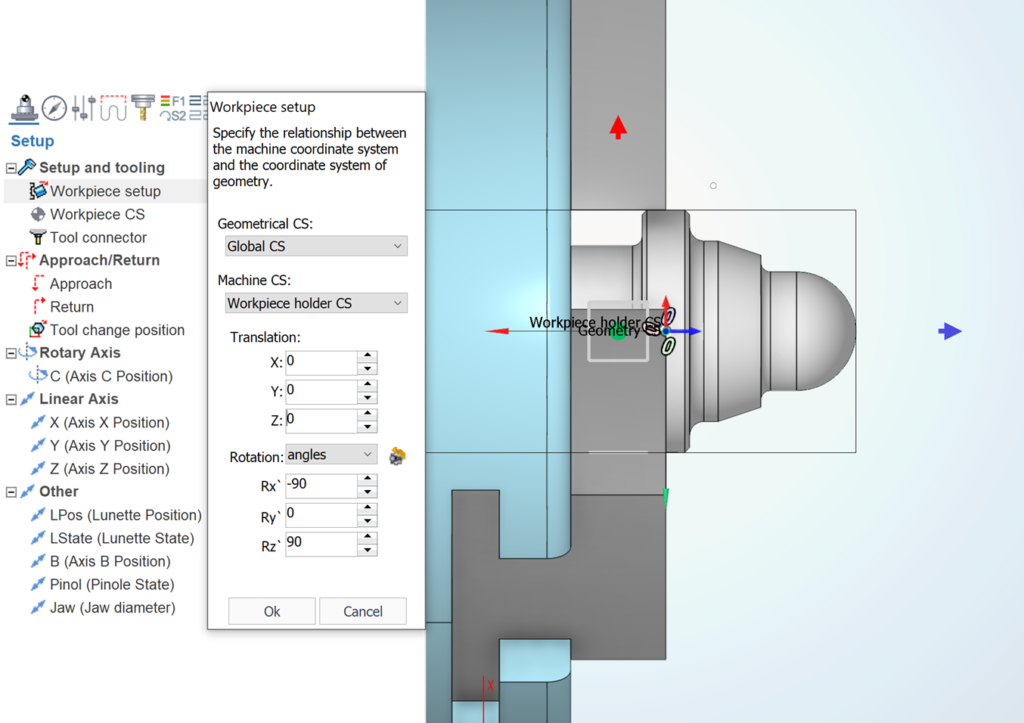

And start setting up the workpiece to the machine. Use transform tools to move, rotate and position the workpiece.

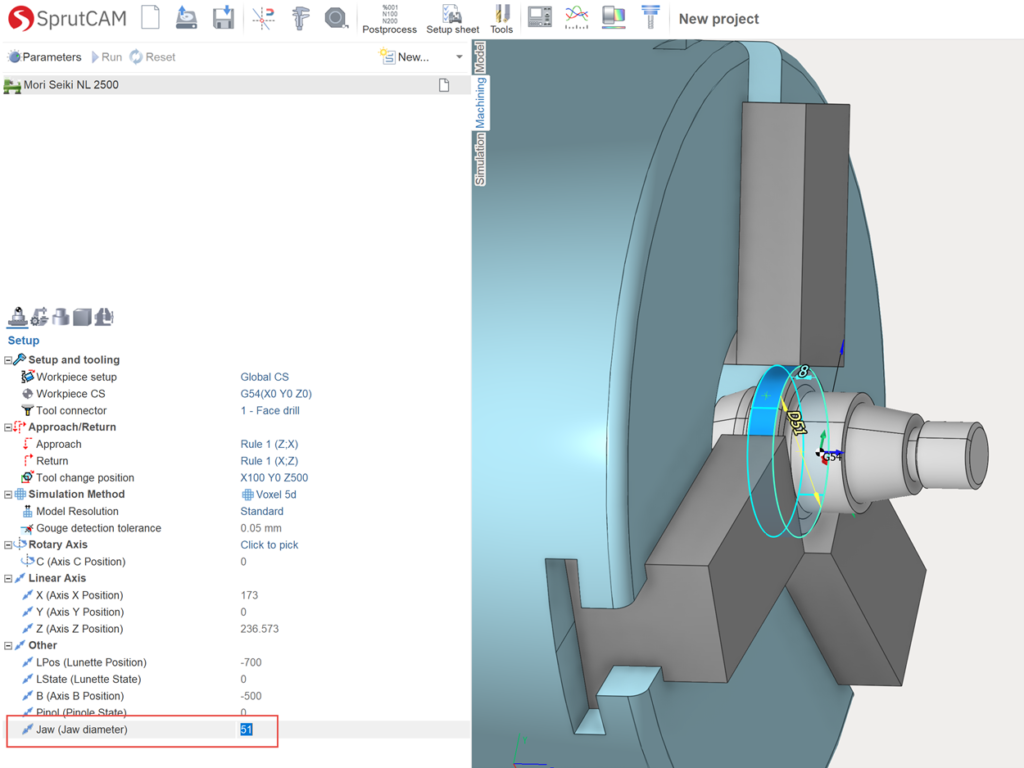

Now fix the workpiece to the chuck using workpiece setup options. Change the jaw diameter to fix the workpiece to the chuck.

Turn the First End

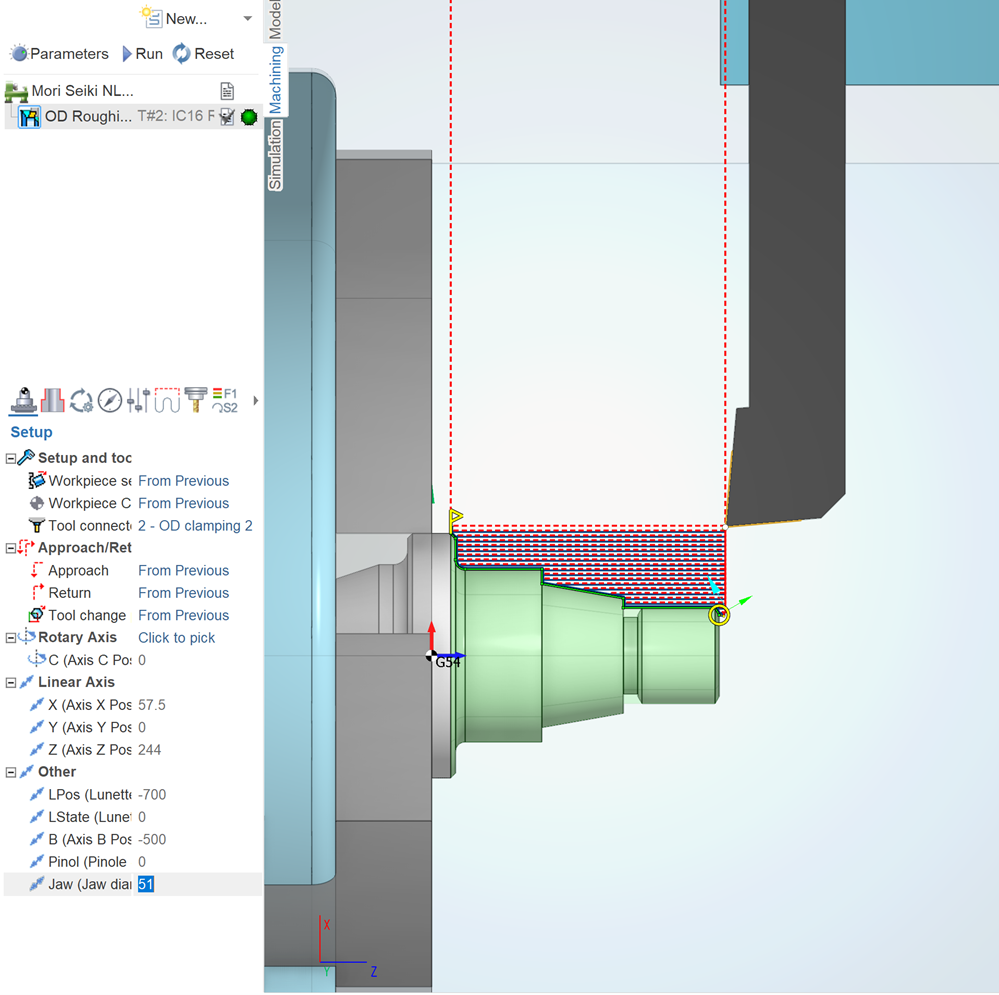

Now it’s time to machine the part based on its available features.

Choose the suitable machining operations from the list, adjust the toolpath based on the required output.

Click on the Run button to generate toolpaths of the same.

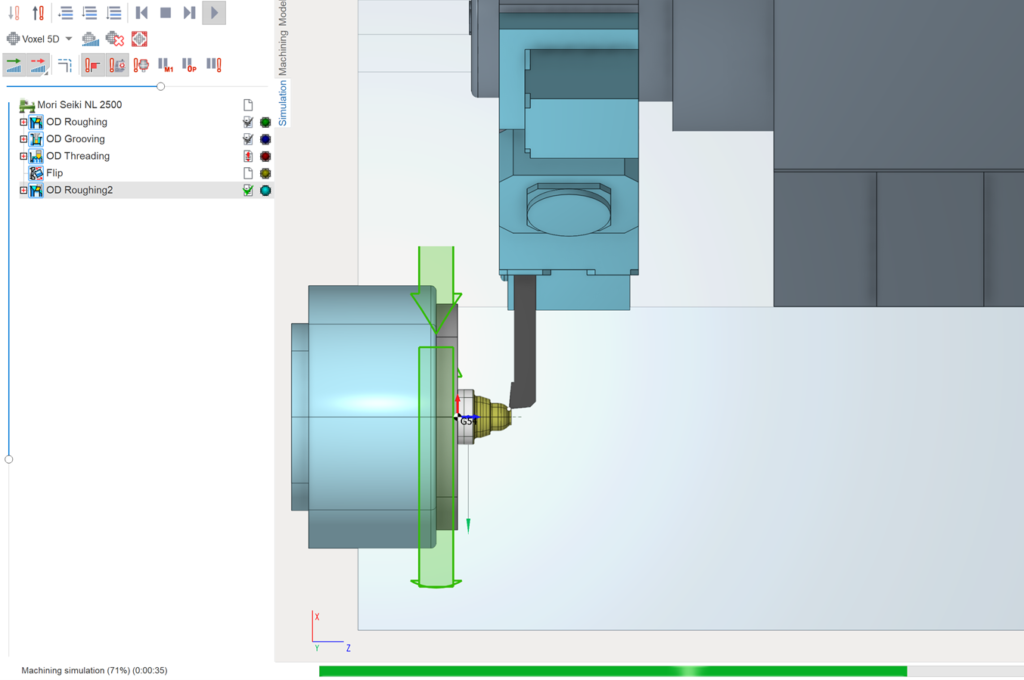

Simulate to check the generated toolpaths.

Stop-Flip the part and Turn the Second Setup

Once the first setup is completed, Move on to the second end.

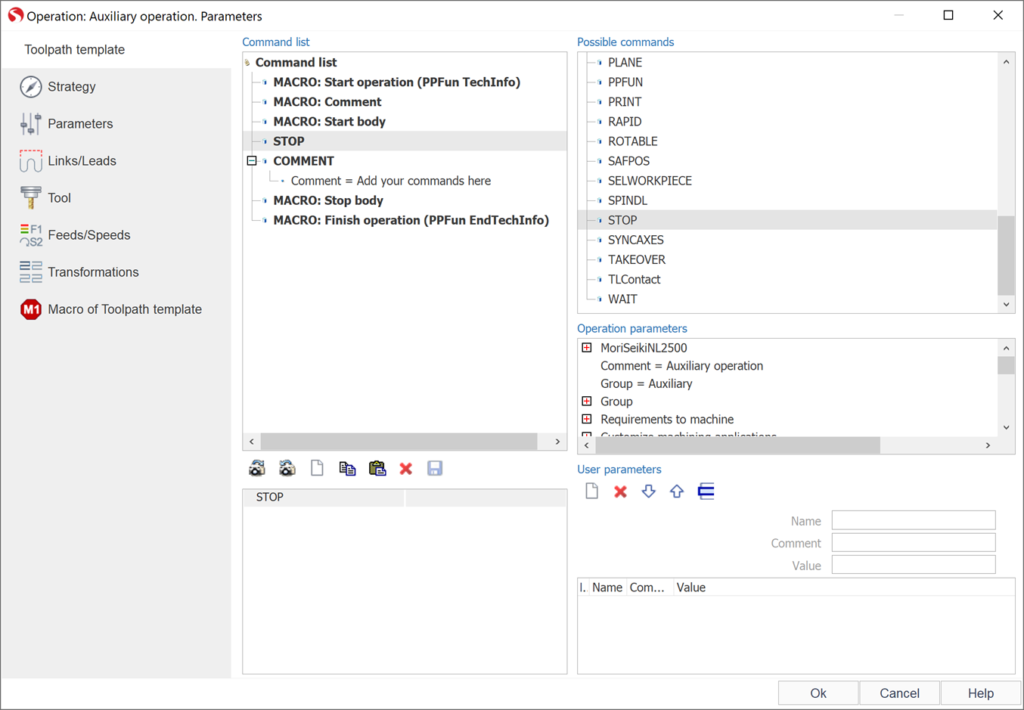

Now we need to stop-flip the part to machine the second end. This can be done by creating the new auxiliary operation that stops (m0 command) the program. For this example, the operation is renamed as a Flip part.

Once this operation is added, Flip the workpiece and fix it to the chuck using workpiece setup options.

Now add the proper operations to the second end features and generate toolpaths.

Simulate to check the generated toolpaths.

For more information on SprutCAM Software and product inquiries, visit us at https://nctools.com.au/ or call us on +61 3 8618 6884