Three ways that SprutCAM 15 can reduce CNC machining time

Using computer numerically controlled (CNC) machining is an important part of designing and manufacturing complex parts. SprutCAM is a system with high levels of automation and a wide range of advanced features and functions. The following are three ways that SprutCAM 15 can reduce CNC machining time.

- Streamlined CNC programming workflow

SprutCAM computes the toolpath for all machining operations based on the native kinematics of the CNC machine. The toolpath calculation automatically avoids collisions between moving parts in the machine and the workpiece as well as with the axis limits. When the toolpath is calculated, all the movements of the machine are immediately visible. The NC code does not need to be post-processed in order to simulate the result. As a result, more machine time is saved.

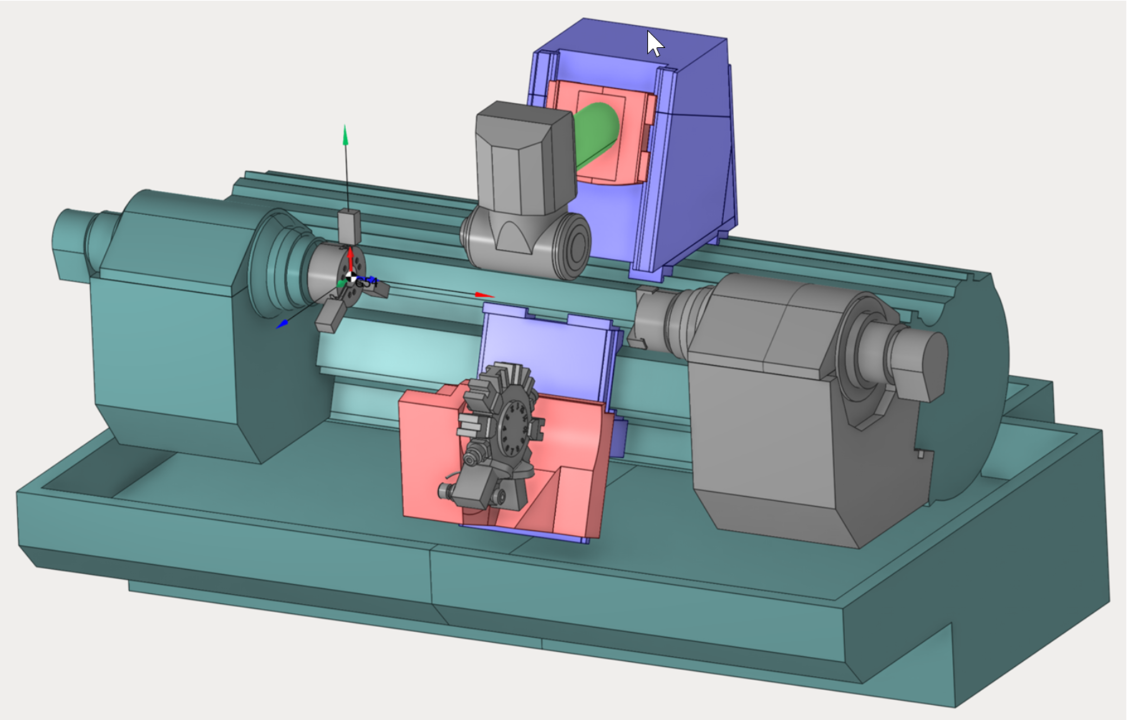

- Multi-Task machining (MTM)

A multi-task machine combines the features of two or more machines in order to machine a single workpiece. SprutCAM is capable of programming multitask turning machines with sub-spindles. Several machines may be combined into one.

In MTM, multiple machines and multiple tools are used simultaneously on one workpiece to reduce the time needed to perform a variety of operations. The same tool can be cut on the same spindle or the parts can be cut on separate spindles. Every tool is controlled by its own program. The multitasking machine has multiple channels.

- Three-axis machining

Automated rest material machining saves time

In order to perform the rest machining in SprutCAM, the area of the part model does not need to be specified. The rest area is automatically detected by SprutCAM. Consequently, the machinist’s time is saved for creating the toolpath and the machine’s time is saved.

Automated hole detection saves time

Select all holes of the same dimension and run the toolpath calculation with one click. This feature is particularly useful for parts with a large number of holes.

Save time by detecting flat faces automatically

In the machining area, SprutCAM automatically detects all flat surfaces.

All 3-axis toolpaths are compatible with multi-axis and mill-turn CNC machines.